When the engine is running, cylinder temperatures rise significantly. If this condition persists, internal components may overheat, reducing efficiency and potentially causing severe damage. To prevent this, coolant circulates continuously through heat-generating parts and dissipates heat via the radiator, helping the engine maintain stable operation.

However, not all coolants are the same. Depending on their chemical additives and production technology, coolants are classified into different types, each suitable for specific vehicles and operating conditions. In this article, we will explore the classification of coolants by technology and color.

The Role of Coolant

The cooling system plays a vital role in maintaining the engine’s optimal temperature during operation. Its main function is to transfer heat away by using coolant to absorb heat from heat-generating parts (such as cylinders and pistons) and release it through the radiator.

To perform effectively in harsh conditions, coolants must meet the following technical requirements:

- High boiling point: Prevents boiling over in high-temperature, continuous, or heavy-load operations.

- Low freezing point: Prevents freezing in cold weather, protecting the system from cracks or blockages.

- Excellent heat transfer: Must quickly dissipate absorbed heat at the radiator to continue the cooling cycle.

- Corrosion and deposit protection: Contains additives that prevent metal corrosion and scaling inside pipes and radiators.

By meeting these requirements, coolant ensures stable engine performance, prolongs engine life, and reduces risks of overheating or freezing.

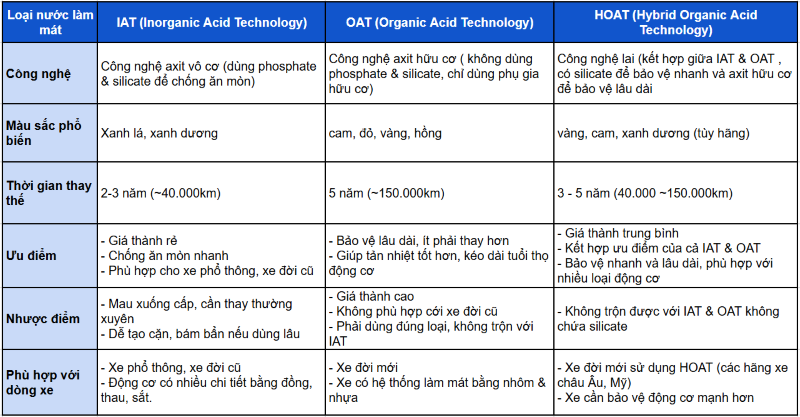

Coolant Classification by Technology

IAT (Inorganic Acid Technology)

IAT uses inorganic additives such as silicates, borates, and phosphates to form a protective layer on metal surfaces inside the cooling system. This prevents oxidation and electrochemical corrosion, especially under fluctuating high temperatures and pressures.

The key advantage of IAT coolant is its immediate formation of a protective layer, effective for engines with cast iron, steel, or copper components prone to corrosion. It is best suited for older or conventional vehicles.

However, IAT also has limitations:

- Short lifespan: typically 2–3 years or about 40,000 km depending on usage.

- Inorganic salts may precipitate and cause scale, reducing cooling efficiency over time.

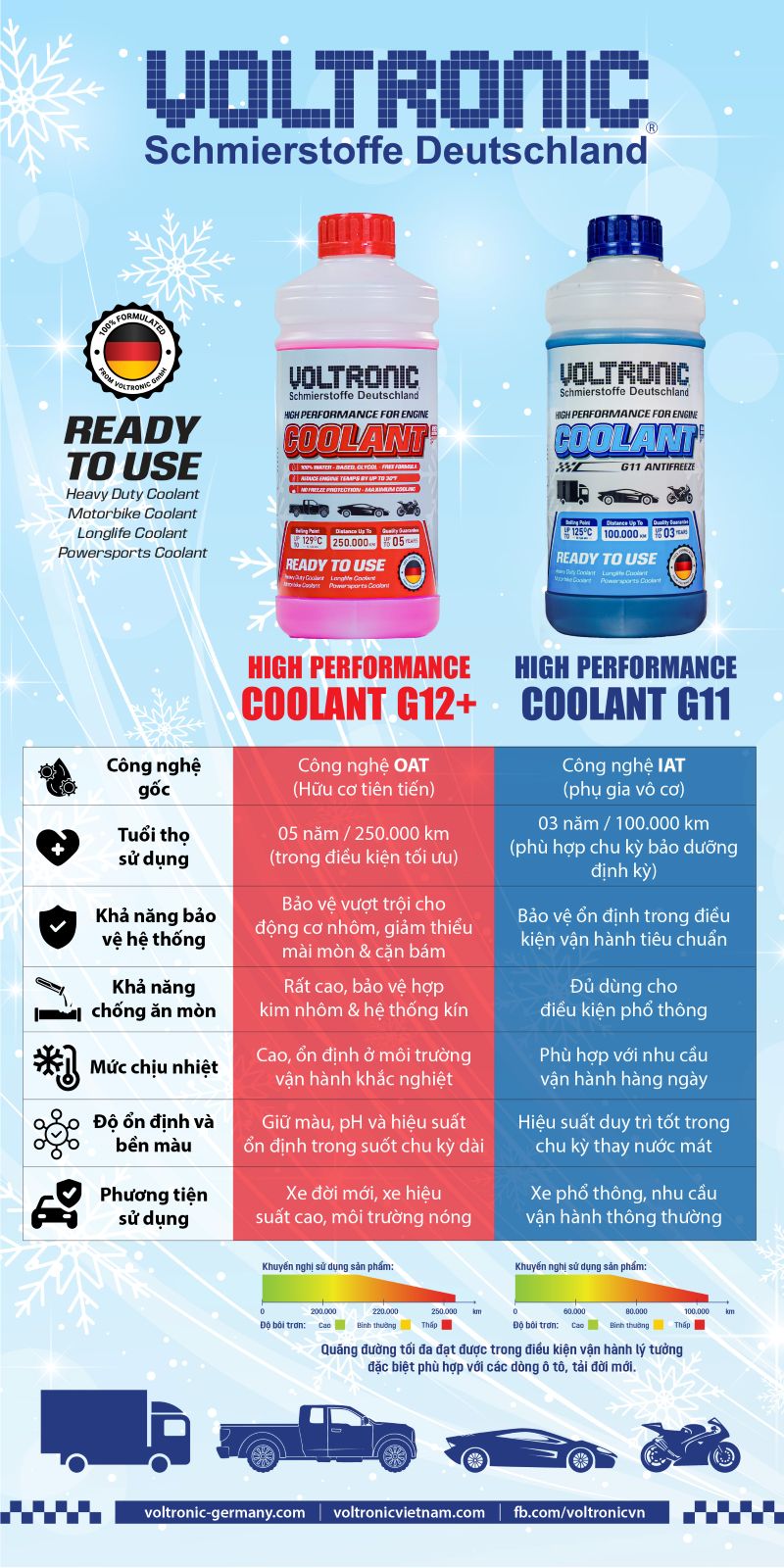

See also: Voltronic High Performance Coolant G11 (IAT technology)

OAT (Organic Acid Technology)

Unlike IAT, which uses inorganic additives prone to deposits, OAT employs organic acids to provide superior anti-corrosion, anti-boiling, anti-freezing, and anti-scaling protection.

OAT forms a durable protective layer only at corrosion-prone points instead of coating the entire surface, reducing additive residue, extending service life, and optimizing cooling efficiency.

Modern OAT coolants typically last up to 5 years or 150,000 km, while Voltronic Coolant G12+ from Germany offers up to 250,000 km, significantly reducing maintenance costs. Free from phosphates and silicates, OAT minimizes scaling, is more eco-friendly, and is ideal for aluminum alloy systems in modern engines.

See also: Voltronic High Performance Coolant G12+ (OAT technology)

OAT is unsuitable for traditional cooling systems with copper, cast iron, or brass components, and must not be mixed with IAT coolants due to chemical incompatibility that may cause sludge and blockages.

HOAT (Hybrid Organic Acid Technology)

HOAT combines the strengths of IAT and OAT: immediate protection from inorganic additives and long-term stability from organic acids. This balanced solution suits modern high-performance cooling systems.

HOAT offers enhanced protection for aluminum components, strong corrosion resistance, and optimal rust prevention. Replacement is recommended every 3–5 years or about 150,000 km.

Coolant Classification by Color

On the market, coolants are also identified by color. While color is not a technical property, it helps users quickly recognize coolant types and technologies:

- Green, blue: IAT technology – for older, conventional vehicles.

- Red, orange, pink: OAT technology – for modern vehicles with aluminum cooling systems.

- Blue, yellow: HOAT technology – commonly found in European vehicles.

Green and Blue Coolants

These coolants are typically IAT-based. Their advantage lies in immediate corrosion protection, ensuring stable performance. Service life is usually 2–3 years or ~40,000 km.

In Vietnam, Voltronic Coolant G11 offers up to 100,000 km (~3 years), thanks to German-imported additives, outperforming standard IAT coolants.

Voltronic G11 features:

- Superior metal protection: Contains silicates and phosphates for excellent protection of copper and iron radiators.

- Stable thermal properties: Ethylene Glycol lowers freezing point and raises boiling point up to 125°C.

- Cost optimization: Provides protection up to 3 years/100,000 km, double the lifespan of standard IAT coolants.

Orange, Red, Pink Coolants

These are OAT-based coolants for modern vehicles with aluminum systems, offering long-lasting corrosion resistance without frequent changes.

The standout is Voltronic Coolant G12+, delivering up to 250,000 km of service life.

Key features of G12+:

- Boiling point up to 17°C higher, ideal for heavy loads or hot climates.

- High compatibility with non-metal materials such as rubber and plastics.

- No silicates, reducing clogging risks.

- Extended service life: up to 5 years or 250,000 km.

Comparison Summary

Understanding coolant classification by technology (IAT, OAT, HOAT) and color helps users select the right coolant for their vehicle. Whether motorcycle or car, using the correct coolant type and replacing it on schedule is essential for performance, corrosion prevention, water pump and radiator protection, and avoiding overheating.

UNIDRAGON GROUP

Address: 2nd Floor, 108 Nguyen Thanh Son, Cat Lai Ward, Ho Chi Minh City

Website: www.unidgroup.vn

Email: harrytran@unidragon.vn / tranquanghuy.eni@gmail.com

Phone: +84 91 773 3543